Step 1

The manufacturing process first involves pulling flat metal ribbon strip through form rolls into a die, which forms a helix and interlocks the material into a convoluted tube; during the process solder (for brass core) or copper wire (for nickel iron and stainless steel) is enclosed in the seam.

Step 2

Second, the solder joints in the brass core, nickel iron core, and stainless steel core seams are completed. The brass core passes through a temperature-controlled oven to melt the solder in the seam. The result is an airtight flexible conduit. The copper wire enclosed in nickel iron and stainless steel products are outsourced for brazing of the copper in the seam. The conduit is processed in a pure hydrogen atmosphere (2000 degrees F) to melt the copper wire in the seam making it an airtight flexible conduit.

Step 3

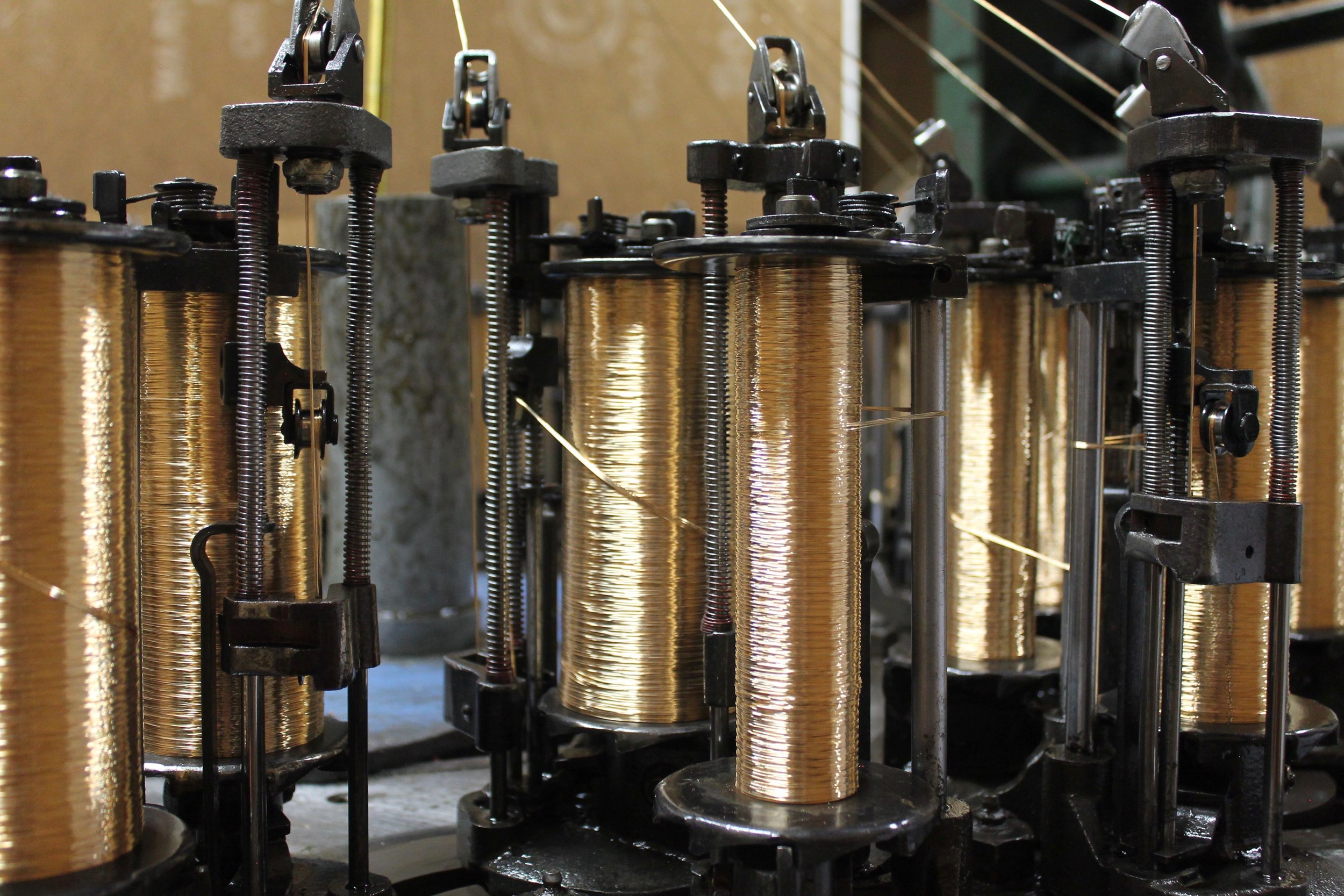

To complete the core manufacturing process the conduit is compressed, greatly improving flexibility, reduces the overall length by 20% to 40%, and increases the weight per foot by a percentage corresponding to the amount of compression. The conduit is tested for leaks by submerging the product into water and applying an internal air pressure of approximately 50-100 PSI. If required the conduit can be over braided using fine wire .006-.016 diameter in a two over two under basket weave pattern.

*Various types of braiding materials are available. Commonly used materials include bronze, nickel, stainless steel, tin, copper, and aluminum. The braiding process is applied according to customer application requirements and specifications. Andrex core assembly line products like our ignition cables are key components in jet engine technology.